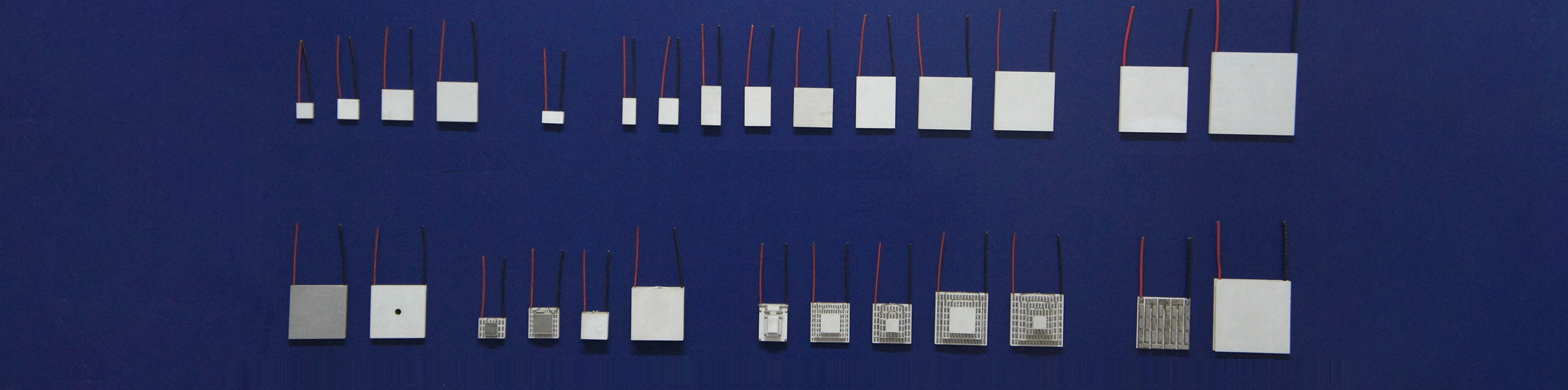

Amamojula okupholisa e-Thermoelectric, imojula ye-Thermoelectric, imojula ye-TEC, indlela yokufaka idivayisi ye-peltier

Ngokuvamile kunezindlela ezintathu zokufakaimodyuli ye-thermoelectricukushisela, ukubopha, ukucindezela nokulungisa ibholidi. Ekukhiqizeni ukuthi iyiphi indlela yokufaka, ngokuya ngezidingo zomkhiqizo, ukunquma, ngokuvamile, ukufakwa kwalezi zinhlobo ezintathu, okokuqala ukusebenzisa ukotini ongenayo i-anhydrous alcohol kuzobai-thermoelectric coolerIzingxenye zobuso obubili obuseceleni zihlanzekile, ipuleti elibandayo kanye nobuso bokufaka ipuleti lokupholisa kufanele kucutshungulwe, ukuthamba komphezulu akudluli ku-0.03mm, futhi kuhlanzekile, okulandelayo yizinhlobo ezintathu zokufakwa kwenqubo yokusebenza.

1. Ukushisela.

Indlela yokufaka ukushisela idinga ukuthi ubuso bangaphandle be-Imodyuli ye-TECkumele kwenziwe ngensimbi, kanti ipuleti elibandayo kanye nepuleti lokupholisa kumele futhi likwazi ukusonta (njenge: ipuleti elibandayo lethusi noma ipuleti lokupholisa). Lapho kufakwa ipuleti elibandayo, ipuleti lokupholisa kanye nedivayisi ye-peltier, i-peltier element, amamojula okupholisa e-thermoelectric, imojula ye-TEC, ipuleti elibandayo kanye nepuleti lokupholisa le-thermoelectric kuqala kuyashiswa, (izinga lokushisa kanye nendawo yokuncibilika kwe-solder kuyafana), i-solder ephansi ephakathi kuka-70 ° C no-110 ° C iyancibilika ebusweni bokufaka. Bese kuthi ubuso obushisayo bedivayisi ye-peltier, imojula ye-peltier, imojula ye-thermoelectric, idivayisi ye-TEC kanye nobuso bokufaka bepuleti lokupholisa, ubuso obubandayo bemojula ye-thermoelectric, idivayisi ye-thermoelectric kanye nobuso bokufaka bepuleti elibandayo kuxhumene ngokufanayo futhi kujikeleziswa ukuze kuqinisekiswe ukuthi ubuso bokusebenza buxhumene kahle ngemva kokupholisa. Indlela yokufaka iyinkimbinkimbi kakhulu, akulula ukuyinakekela, futhi ivame ukusetshenziswa ngezikhathi ezikhethekile.

2. Iglu.

Ukufakwa kwe-glue kimii-thod iwukusebenzisa ingcina enokushisa okuhle, embozwe ngokulinganayo ebusweni bokufakwa kwemodyuli yokupholisa ye-Thermoelectric,, ipuleti elibandayo kanye nepuleti lokupholisa. Ubukhulu besinamathelisi bungu-0.03mm, ubuso obubandayo nobushisayo bedivayisi ye-peltier, iseli le-peltier, imodyuli ye-TEC, imodyuli ye-thermoelectric kanye nobuso bokufaka ipuleti elibandayo kanye nepuleti lokusabalalisa ukushisa kukhishwe ngokuhambisana, bese kujikeleziswa ngobumnene emuva naphambili ukuqinisekisa ukuthi indawo yokuxhumana ixhumana kahle, futhi umoya ufakwa amahora angama-24 ukuze uphole ngokwemvelo. Indlela yokufaka ngokuvamile isetshenziselwa ukulungisa unomphela idivayisi yokupholisa ye-thermoelectric, iseli le-peltier, idivayisi yokupholisa ye-thermoelectric, endaweni yepuleti lokusabalalisa ukushisa noma ipuleti elibandayo.

3. Ukucindezelwa nokulungiswa kwe-stud.

Indlela yokufaka yokuqinisa i-stud ukumboza ngokulinganayo ubuso bokufaka be-studimodyuli ye-peltieripuleti elibandayo kanye nepuleti lokushabalalisa ukushisa elinesendlalelo esincane samafutha e-silicone ashisayo, ubukhulu bawo obungaba ngu-0.03mm. Bese kuba ubuso obushisayo be-i-peltier coolerkanye nobuso bokufakwa kwepuleti lokupholisa, ubuso obubandayo bamadivayisi e-peltier, amamojula okupholisa e-thermoelectric kanye nobuso bokufakwa kwepuleti elibandayo kuxhumene ngokufana, futhi ujikeleze kancane imojula ye-TEC, imojula ye-thermoelectric ibuyele emuva naphambili, ukhiphe amafutha amaningi okushisa, qiniseka ukuthi indawo yokusebenza ixhumene kahle, bese uqinisa phakathi kwepuleti lokupholisa, imojula ye-Thermoelectric, imojula ye-Peltier, imojula ye-TEC, imojula yokupholisa ye-thermoelectric kanye nepuleti elibandayo ngezikulufo, amandla okubopha kufanele afane, angadluli kakhulu noma alula kakhulu. Okusindayo kulula ukuchoboza isiqandisi, futhi ukukhanya kulula ukwenza ubuso obusebenzayo bungaxhumani. Ukufakwa kulula, kuyashesha, kulula ukugcinwa, ukuthembeka okuphezulu, okwamanje kuyindlela esetshenziswa kakhulu ekusetshenzisweni komkhiqizo kwenye yezindlela zokufaka.

Izindlela ezintathu zokufaka ezingenhla ukuze kufezwe umphumela omuhle kakhulu wokupholisa, ukusetshenziswa kwezinto zokuvikela phakathi kwepuleti elibandayo nepuleti lokupholisa, ukusetshenziswa kwe-washer yokuvikela ukushisa, ukuze kuncishiswe ukushintshashintsha okushisayo nokubandayo, usayizi wepuleti elibandayo lokupholisa i-thermoelectric kanye nepuleti lokupholisa kuncike endleleni yokupholisa kanye nosayizi wamandla okupholisa, ngokuya ngesimo sesicelo.

Imodyuli yokupholisa ye-thermoelectric TES1-01009LT125

Isilinganiso: 0.9A,

Ubukhulu: 1.3V

I-Qmax: 0.65W

Ubukhulu be-Delta T: 72C

I-ACR: 1.19﹢/﹣0.1Ω

Usayizi: 2.4×1.9×0.98mm

Imojula ye-thermoelectric eyindilinga nephakathi nendawo yembobo ye-TES1-13905T125

Izinga lokushisa elishisayo eliseceleni lingu-25 C,

Isilinganiso: 5A,

Umax:15-16 V

I-Qmax:48W

Ubukhulu be-Delta T: 67 C

Ukuphakama: 3.2+/- 0.1mm

Usayizi: Ububanzi bangaphandle: 39+/- 0.3mm, Ububanzi bangaphakathi: 9.5mm +/- 0.2mm,

Ubude bentambo yekhebula le-PVC engu-22AWG: 110mm +/- 2mm

Imodyuli ye-thermoelectric TES1-3202T200 Imininingwane

Isilinganiso: 1.7-1.9A,

Ubukhulu: 2.7V

I-Qmax:3.1W

Ubukhulu be-Delta T: 72C

I-ACR: 1.42-1.57Ω

Usayizi: 6 × 8.2 × 1.6-1.7mm

Isikhathi sokuthunyelwe: Novemba-28-2024