Izinhlelo zokusebenza zamamojula okupholisa i-thermoelectric

Ingqikithi yomkhiqizo wohlelo lokupholisa lwe-thermoelectric yi-thermoelectric cooling module. Ngokwezici, ubuthakathaka kanye nobubanzi bokusetshenziswa kwe-thermoelectric stack, izinkinga ezilandelayo kufanele zinqunywe lapho kukhethwa i-stack:

1. Nquma isimo sokusebenza sezinto zokupholisa ze-thermoelectric. Ngokuya ngesiqondiso nosayizi wamandla okusebenza, unganquma ukusebenza kokupholisa, ukushisa kanye nokushisa okungaguquki kwe-reactor, yize indlela evame ukusetshenziswa kakhulu kuyindlela yokupholisa, kodwa akufanele ungayinaki indlela yayo yokushisa nokusebenza kokushisa okungaguquki.

2, Nquma izinga lokushisa langempela lengxenye eshisayo lapho upholisa. Ngenxa yokuthi i-reactor iyidivayisi yokwehluka kwezinga lokushisa, ukuze kufezwe umphumela omuhle kakhulu wokupholisa, i-reactor kumele ifakwe ku-radiator enhle, ngokuya ngezimo ezinhle noma ezimbi zokushabalalisa ukushisa, nquma izinga lokushisa langempela lengxenye eshisayo ye-reactor lapho upholisa, kufanele kuqashelwe ukuthi ngenxa yethonya le-gradient yokushisa, izinga lokushisa langempela lengxenye eshisayo ye-reactor lihlala liphakeme kunezinga lokushisa lobuso be-radiator, ngokuvamile lingaphansi kwezinga eliyishumi le-degree, ngaphezu kwezinga elimbalwa, ama-degree ayishumi. Ngokufanayo, ngaphezu kwe-gradient yokushabalalisa ukushisa ekugcineni okushisayo, kukhona futhi i-gradient yokushisa phakathi kwesikhala esipholile kanye nengxenye ebandayo ye-reactor.

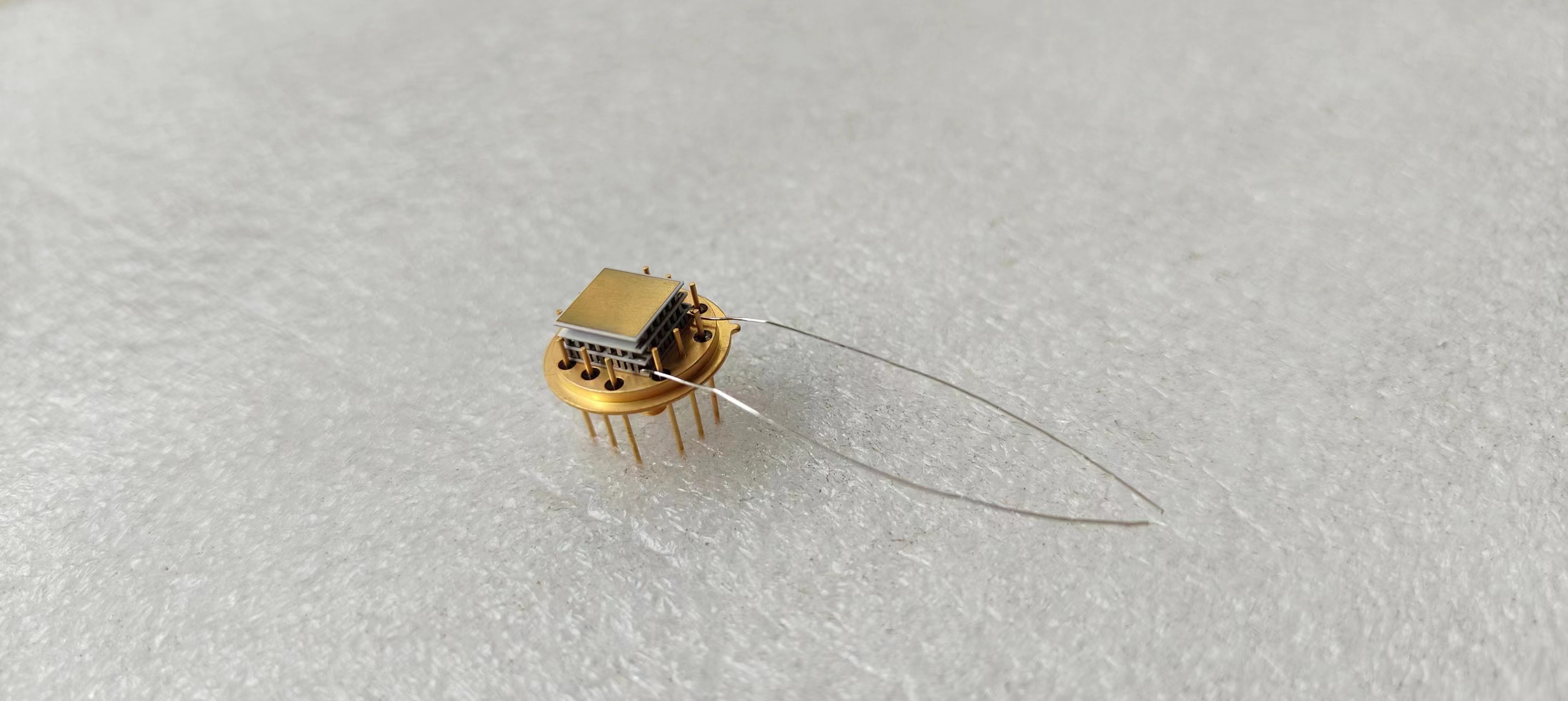

3, Nquma indawo yokusebenza kanye nomoya we-reactor. Lokhu kufaka phakathi ukuthi amamojula e-TEC, amamojula okupholisa e-thermoelectric azosebenza ku-vacuum noma emoyeni ojwayelekile, i-nitrogen eyomile, umoya omile noma ohambayo kanye nokushisa okuzungezile, lapho kubhekwa khona izinyathelo zokushisa (adiabatic) futhi kunqunywa umphumela wokuvuza kokushisa.

4. Nquma into esebenzayo yezinto ze-thermoelectric kanye nosayizi womthwalo wokushisa. Ngaphezu kwethonya lokushisa kwe-hot end, izinga lokushisa eliphansi noma umehluko omkhulu wokushisa izinto ze-TEC N,P ezingawufinyelela unqunywa ngaphansi kwezimo ezimbili zokungalayishi kanye ne-adiabatic, empeleni, izinto ze-peltier N,P azikwazi ukuba yi-adiabatic ngempela, kodwa futhi kumele zibe nomthwalo wokushisa, ngaphandle kwalokho akunamsebenzi.

5. Nquma izinga le-thermoelectric module, i-TEC module (izinto ze-peltier). Ukukhethwa kochungechunge lwe-reactor kumele kuhlangabezane nezidingo zomehluko wangempela wokushisa, okungukuthi, umehluko wokushisa ojwayelekile we-reactor kumele ube phezulu kunomehluko wangempela wokushisa odingekayo, ngaphandle kwalokho awukwazi ukuhlangabezana nezidingo, kodwa uchungechunge alukwazi ukuba lukhulu kakhulu, ngoba intengo ye-reactor ithuthukiswa kakhulu ngokwanda kochungechunge.

6. Imininingwane yezinto ze-thermoelectric N,P. Ngemva kokukhethwa kochungechunge lwento ye-peltier device N,P, imininingwane yezinto ze-peltier N,P, ingakhethwa, ikakhulukazi amandla okusebenza ezinto ze-peltier cooler N,P. Ngoba kunezinhlobo eziningana zama-reactors angahlangabezana nomehluko wokushisa kanye nokukhiqizwa okubandayo ngesikhathi esisodwa, kodwa ngenxa yezimo zokusebenza ezahlukene, i-reactor enomthamo omncane kakhulu wokusebenza ivame ukukhethwa, ngoba izindleko zamandla asekelayo zincane ngalesi sikhathi, kodwa amandla aphelele e-reactor yiwona anqumayo, amandla okufaka afanayo okunciphisa amandla okusebenza kufanele akhulise i-voltage (0.1v ngezingxenye ezimbili), ngakho-ke i-logarithm yezingxenye kufanele ikhuphuke.

7. Nquma inani lezinto ze-N,P. Lokhu kusekelwe emandleni okupholisa aphelele e-reactor ukuze kuhlangatshezwane nezidingo zomehluko wokushisa, kumele kuqinisekiswe ukuthi inani lomthamo wokupholisa we-reactor ekushiseni kokusebenza likhulu kunamandla aphelele omthwalo wokushisa wento esebenzayo, ngaphandle kwalokho ngeke ihlangabezane nezidingo. I-inertia yokushisa ye-stack incane kakhulu, ayidluli umzuzu owodwa ngaphansi komthwalo ongekho, kodwa ngenxa ye-inertia yomthwalo (ikakhulukazi ngenxa yomthamo wokushisa womthwalo), isivinini sangempela sokusebenza sokufinyelela izinga lokushisa elibekiwe sikhulu kakhulu kunomzuzu owodwa, futhi sithatha amahora amaningana. Uma izidingo zesivinini sokusebenza zikhulu, inani lama-piles lizoba ngaphezulu, amandla aphelele omthwalo wokushisa akhiwa umthamo wokushisa ophelele kanye nokuvuza kokushisa (uma izinga lokushisa liphansi, kulapho ukuvuza kokushisa kuba kukhulu).

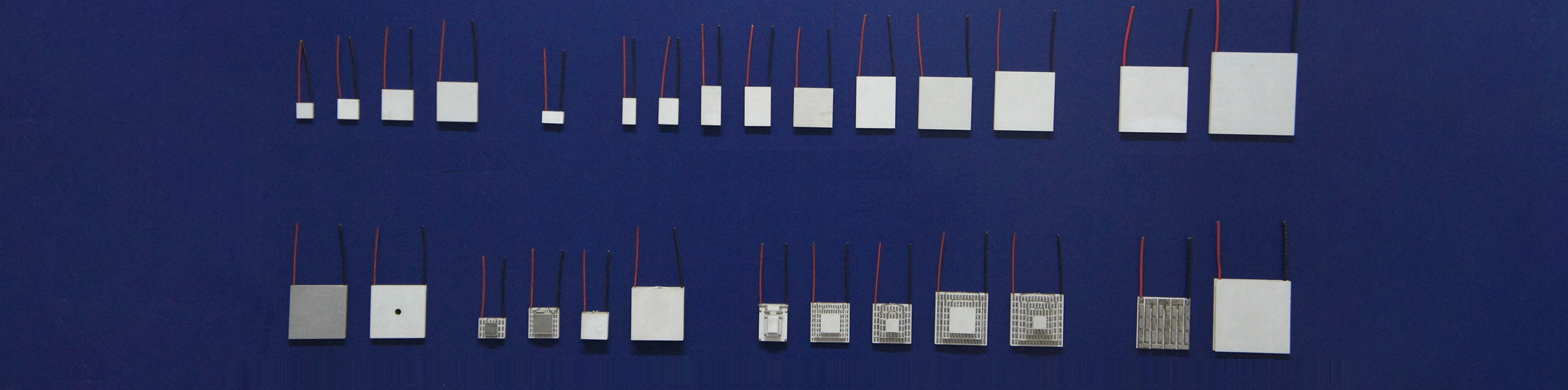

Izici eziyisikhombisa ezingenhla ziyizimiso ezijwayelekile okufanele zicatshangelwe lapho kukhethwa imodyuli ye-thermoelectric N,P, izakhi ze-peltier, lapho umsebenzisi wokuqala kufanele aqale akhethe khona amamojula okupholisa e-thermoelectric, i-peltier cooler, imodyuli ye-TEC ngokuya ngezimfuneko.

(1) Qinisekisa ukusetshenziswa kwezinga lokushisa elizungezile i-Th ℃

(2) Izinga lokushisa eliphansi i-Tc ℃ elifinyelelwe yisikhala noma into epholile

(3) Umthwalo wokushisa owaziwayo Q (amandla okushisa Qp, ukuvuza kokushisa Qt) W

Uma kubhekwa i-Th, i-Tc kanye ne-Q, i-Thermoelectric cooler edingekayo izakhi ze-N,P kanye nenani lezakhi ze-TEC N,P kungalinganiswa ngokuya ngejika eliyisici lamamojula okupholisa e-thermoelectric, i-peltier cooler, amamojula e-TEC.

Isikhathi sokuthunyelwe: Novemba-13-2023