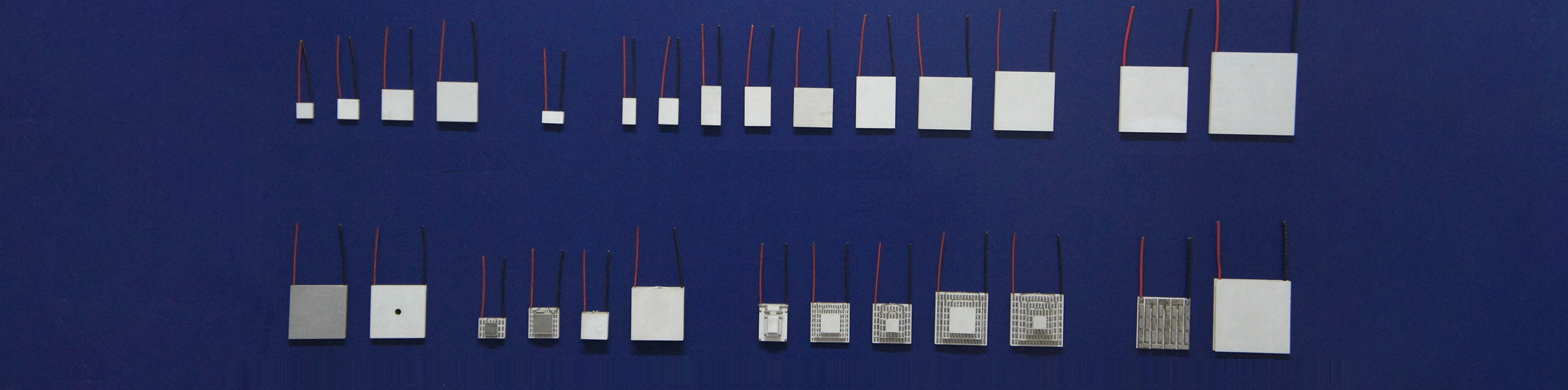

Ukusetshenziswa kwe-thermoelectric module (eyaziwa nangokuthi ama-thermoelectric cooling modules, i-TEC, noma i-Thermoelectric Cooler) kudivayisi yokuvuselela isikhumba se-photon ngokuyinhloko kuhloselwe ukufeza umsebenzi wokupholisa, ukuze kuthuthukiswe induduzo nokuphepha ngesikhathi senqubo yokwelapha. Nansi incazelo eningiliziwe yama-thermoelectric cooling modules, ama-thermoelectric modules, ama-TEC, ama-peltier modules kudivayisi yokuvuselela isikhumba se-photon:

1. Isimiso sokusebenza

Imodyuli ye-thermoelectric isekelwe kumphumela we-Peltier: Lapho ugesi oqondile udlula kubhangqa lwe-thermoelectric olwakhiwe ngezinto ze-semiconductor zohlobo lwe-N kanye nohlobo lwe-P, uhlangothi olulodwa lumunca ukushisa (uhlangothi olubandayo) kanti olunye uhlangothi lukhipha ukushisa (uhlangothi olushisayo). Kudivayisi yokuvuselela isikhumba se-photon:

Ingxenyana ebandayo iseduze nesikhumba noma ikristalu eqondisa ukukhanya, esetshenziselwa ukupholisa

Ingxenye eshisayo ixhunywe kusinki yokushisa (njengefeni noma uhlelo lokupholisa amanzi), ukuze kukhishwe ukushisa

2. Imisebenzi eyinhloko kudivayisi yokuvuselela isikhumba se-photon Vikela isikhumba

Ukukhanya okukhulu okushaywayo (i-IPL) noma i-laser imisebe kudala ukushisa, okungase kubangele ukusha noma ukungakhululeki. Iphedi yokupholisa inganciphisa ngokushesha izinga lokushisa kwesikhumba futhi inciphise ingozi yokulimala kokushisa.

Thuthukisa induduzo

Umuzwa wokupholisa unganciphisa kakhulu ubuhlungu noma umuzwa wokushisa ngesikhathi sokwelashwa, okuthuthukisa ulwazi lomsebenzisi.

Thuthukisa ukusebenza kahle

Ngemva kokuba i-epidermis isipholile, amandla angagxila kakhulu ezicutshini eziqondiwe (njengezimbotshana zezinwele, amaseli e-pigment), okuthuthukisa ukusebenza kahle kwesenzo sokushisa kwe-photothermal esikhethiwe.

Vimbela ukuguquka kombala

Ukulawula izinga lokushisa okuphumelelayo kunganciphisa ingozi yokwanda kwe-pigmentation ngemva kokuhlinzwa (PIH), ikakhulukazi kubantu abanesikhumba esimnyama.

3. Izindlela Zokuhlela Ezivamile

Ukupholisa kokuthinta: Iphedi yokupholisa kungaba ngokuqondile noma ngefasitela le-sapphire/silicon optical ithinta isikhumba

Ukupholisa okungenakuthintana: Kuhlanganiswe nosizo lomoya obandayo noma ijeli, kodwa ukupholisa kwe-semiconductor kuhlala kungumthombo oyinhloko wokupholisa

I-TEC enezigaba eziningi, imoduli ye-thermoelectric enezigaba eziningi: Imishini ephezulu ingasebenzisa ama-cooling pad amaningi ukuze kufinyelelwe amazinga okushisa aphansi (njenge-0-5℃)

4. Izinyathelo Zokuqapha

Ukusetshenziswa kwamandla kanye nokushabalalisa ukushisa: Imodyuli ye-Peltier, imodyuli ye-TEC idinga ugesi omkhulu, futhi ingxenye eshisayo kumele ibe nokushabalalisa ukushisa okuphumelelayo; ngaphandle kwalokho, ukusebenza kahle kokupholisa kuzokwehla kakhulu noma kulimaze idivayisi.

Inkinga yamanzi okuminyana: Uma izinga lokushisa lobuso liphansi kunephuzu lamazolo, amanzi okuminyana angase akheke, futhi kudingeka ukwelashwa okungangeni manzi/ukuvikela

Ukuphila nokuthembeka: Ukushintsha njalo noma izindawo ezishisa kakhulu kuzofinyeza isikhathi sokuphila semodyuli ye-TEC. Kunconywa ukusebenzisa izingxenye zezinga lezimboni

Imininingwane ye-TES1-17710T125

Izinga lokushisa elishisayo eliseceleni lingu-30 C,

Isilinganiso: 10.5 A,

Umax: 20.9V

I-QMax: 124 W

I-ACR: 1.62 ±10% Ω

Ubukhulu be-Delta T: > 65 C

Usayizi: phansi 84 × 34 mm, phezulu: 80x23 mm, ukuphakama: 2.9 mm

Umgodi ophakathi: 60x 19 mm

Ipuleti le-Ceramic: 96%Al2O3

Ivaliwe: Ivaliwe yi-703 RTV (umbala omhlophe)

Ikhebula: 18 AWG izinga lokushisa lokumelana nentambo 80℃.

Ubude bekhebula: 100mm, umucu wocingo kanye nethini ene-Bi Sn solder, 10mm

Izinto ze-thermoelectric: i-Bismuth Telluride

Isikhathi sokuthunyelwe: Jan-14-2026